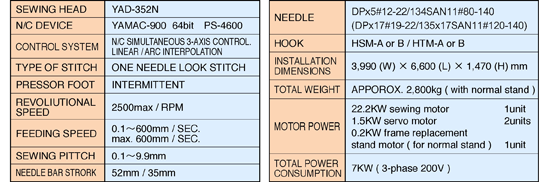

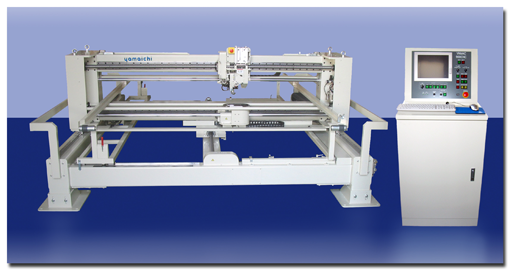

Fully Automatic Numerical Control Quilting Machine |

||||

Model : Y&Y-S900CNC-2 |

||||

|

|

|

|

||||

|

|

Y&Y-S900CNC-2 Catalogue download of PDF data(730k) |

|

Get Acrobatェ Reader | |

| MECHANISM | |

|

・

|

As employ 64 bit computer, data processing is faster than conventional machine. |

|

・

|

Programs can be stored into built-in hard disk . |

|

・

|

It's equipped with an USB port in an enternal memoty. |

|

・

|

Easy replacement of quilts The sewing head vertical rises at the end of a quilting process to |

| allow for a sufficient clearance for easy replacement of the quilting work frames. | |

|

・

|

Automatic lubrication system for sewing head and hook by use of pneumatic jet fog. |

|

・

|

Photoelectric needle thread disconnection sensor. |

| Automatic stop upon detection of needle thread disconnection, automatic carry the thread |

|

| change position and original position return the memory of thread disconnected position. | |

| (Patent registered) | |

|

・

|

Automatic bobbin thread cutting device. |

|

・

|

Efficient feeding system by using boll screw to feed back and forth, right and left the sewing |

| head and the hook base. | |

|

・

|

Double over-run prevention system for software and hardware. |

|

・

|

Safety device is equipped on the machine for safety operation. |

|

・

|

The sewing head, which was designed and developed specifically for comforter quilting |

| machine, has been improved in its high speed stability and durability. | |

| ・ | The rapid rotation type sewing machie head of new development is adopted. |

| FEATURES | |

|

・

|

Main motor, which is capable of operating at varied speeds. |

| Sewing speed and feeding speed can be varied according to the program. | |

|

・

|

Quilt loading and unloading can be made easily. |

| When sewing is finished, sewing needle is stopped at upper position and sewing head is lifted |

|

| the wide spac thus produced facilitates the replacement of quilt frame. | |

|

・

|

When the thread is disconnected, the point where it occurred is recorded in the memory. |

| After the thread is repaired, the pattern program can be run in reverse and the sewing can be |

|

| restarted from any desired point. (High accurate electronic control makes overlapped |

|

| stitches at the restarting point hard to detect.) | |

| The return to the original position can be made directly when the step number is specified. | |

|

・

|

Enlargement / reduction of quilting pattern size, coupled with pattern shift function, enables |

| quick adjustment to various sizes of quilts. | |

|

・

|

Equipped with production control system. |

| Output per each pattern / The total output / The total operation time / The rate of actual |

|

| operation on the day / The frequency of thread breakage on the day / Stitching time per one |

|

| piece. | |

|

・

|

Stitch patterns are indicated on CRT Monitor graphically. |

| (Display of Automatic operation and program making.) | |

|

・

|

Routine pattern, WAVE and SCALLOP are stored in advance and possible to input only with |

| programs of start point and end point, same as straight pattern. The time of pattern making |

|

| is reduced 80%, compared with conventional type machine. | |

|

・

|

Possible to make program of new stitch pattern during automatic operation. |

|

・

|

With of quilt frame guide width can be adjusted by one-touch action. (PAT.P) |

|

・

|

Only one time, the machine needs set original position, when set-up the machine. |

| After that, the machine dose not needs operation of back to original position. | |

|

・

|

Sewing pitch can be adjusted on the screen, (0.1~9.9mm). Sewing pitches are always same |

| as adjusted pitch by operator. | |

| **Red characters are new function for S900CNC-2. | |

_id_(e).png)